Well to Tank Energy Efficiencies for Gasoline

Getting to Half Oil

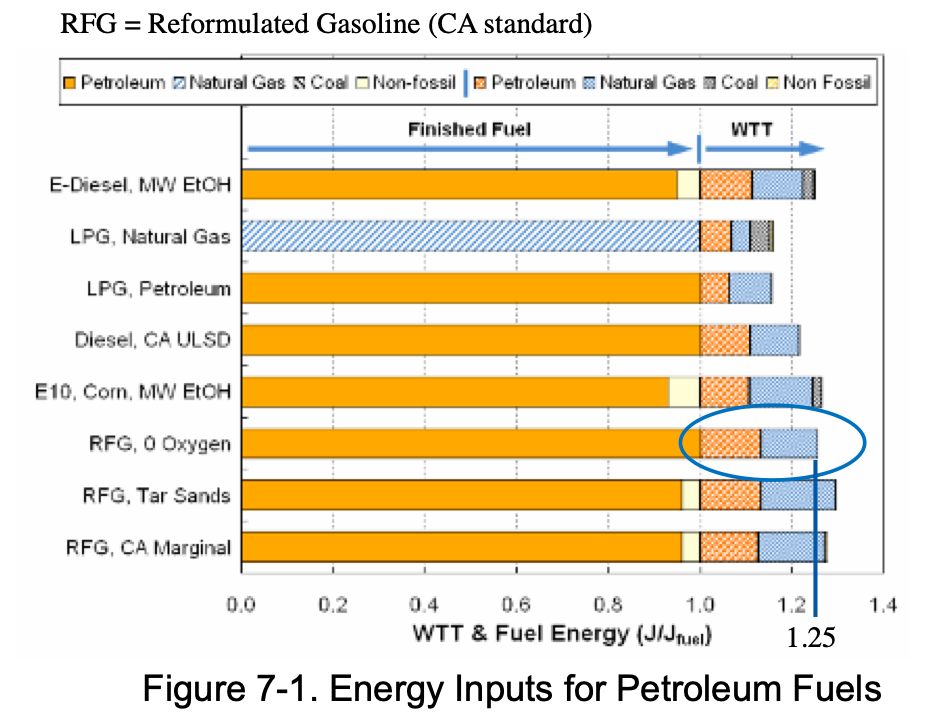

Well-to-Tank (WTT) energy efficiencies for gasoline and diesel production are quite high. Compared to energy delivered per gallon of gasoline or diesel, an additional 25% of the energy content is needed from well to tank. Per gallon of fuel the embedded energy consumed in feedstock recovery, processing, storage and transportation, plus fuel production, transportation, storage and distribution is 25% over and above the energy delivered.

This is known from a study chartered by the California Energy Commission, 2007:

Full Fuel Cycle Assessment: Well to Tank Energy Inputs, Emissions, and Water Impacts, TIAX LLC

The energy content of a gallon of gasoline is 33.7kWh, so the additional WTT energy needed to produce and deliver it to a vehicle tank is 8.4kWh. The refinery process alone accounts for consumption of 4.5kWh. This is reported from the following link (which also includes considerable entertainment content).

The energy content of a gallon of gasoline is 33.7kWh, so the additional WTT energy needed to produce and deliver it to a vehicle tank is 8.4kWh. The refinery process alone accounts for consumption of 4.5kWh. This is reported from the following link (which also includes considerable entertainment content).

With a typical Battery Electric Vehicle (BEV) consuming energy at 3.5mi/kWh, this vehicle can travel over 25 mi using only the production energy embedded in a gallon of gasoline or diesel. For a passenger BEV (Nissan Leaf, any Tesla, Volt or Bolt) the range achieved is 3.5mi/kWh x 8.4 kWh = 29mi

This means every passenger BEV travelling 29 mi actually bypasses the need to drill for, refine and deliver a gallon of gasoline or diesel.

Of all US petroleum consumed 73% goes to transportation, 27% to industrial production. Total petroleum 2018: 19.3M bbl/day.

Industrial: 5.13M bbl/day (27%)

Transportation: 14.16M bbl/day (73%)

https://www.eia.gov/totalenergy/data/monthly/pdf/flow/petroleum.pdf

This suggests that the best prospects for reducing oil demand to half by 2035 are found in reducing demand for petroleum in transportation. This is the premise of the Union of Concerned Scientists’ Half The Oil plan. Half Oil for the transportation sector of the US economy can be achieved when half of all vehicles consume an alternative fuel. Given the nature of air travel technology (fuel dependent turbine technology) and rail transport (already refined for highly efficient diesel-electric traction), alternative fuel for truck transportation deserves immediate attention. This is because petroleum consumed by cars alone amounts to less than half of the total.

Passenger vehicles make up 44% of the transportation sector, trucks 53%.

Total vehicles reported 2014, US DOT: 253M

Total cars: 111M/253M = 44%

Total cars: 133M/253M = 53%

http://www.fhwa.dot.gov/policyinformation/statistics/2012/mv1.cfm

Taking only the passenger vehicle fraction of 44%, the net share of passenger vehicle petroleum consumption for cars is

44% x 72 % = 31%

Available BEV models are increasing and cost is decreasing, making the automobile alternative fuel the most leveraged in progressing toward Half Oil.

About Electric Trucks

Proliferation of electric drive trains for trucks is seriously impeded by cost. The typical BEV truck price point is at least 2x over the conventional diesel or gasoline power train. Compared to the rapid transition of passenger cars to BEV drive train technology, very few fleets have begun testing the BEV in revenue service. Half Oil will be well served when an economical drive train design is developed that makes conversion of diesel service vehicles appealing to fleet operators.

Proliferation of electric drive trains for trucks is seriously impeded by cost. The typical BEV truck price point is at least 2x over the conventional diesel or gasoline power train. Compared to the rapid transition of passenger cars to BEV drive train technology, very few fleets have begun testing the BEV in revenue service. Half Oil will be well served when an economical drive train design is developed that makes conversion of diesel service vehicles appealing to fleet operators.

Better Energy LLC is planning to field an inexpensive conversion that can be safely deployed on a large scale while relying only on conventional technologies. This means acknowledging the inherent risk of working with 600VDC drive motors, motor controllers and battery packs. Electric bus and light rail streetcars deployed in metropolitan centers are already supported by the necessary safe practices. Better Energy LLC has developed a safety handbook to consolidate best practices that can be broadly disseminated with shop training.

To achieve a goal of reducing total demand for petroleum to 50%, a reduction of the 73% transportation share to 22% is suggested by the math. Knowing the genesis of automobile BEV technology together with its production stimulus and market acceptance, equally effective incentives are obviously needed for a transition to electric truck technology. Sustainable drive train conversions that conserve the energy embodied in the truck’s original production will make it economically practical for business to participate in reducing petroleum demand, and which is needed in the near term.

— Better Energy, LLC